Soldering Flux Syringe 10g (NC-559)

Delivery: 2-5 working days

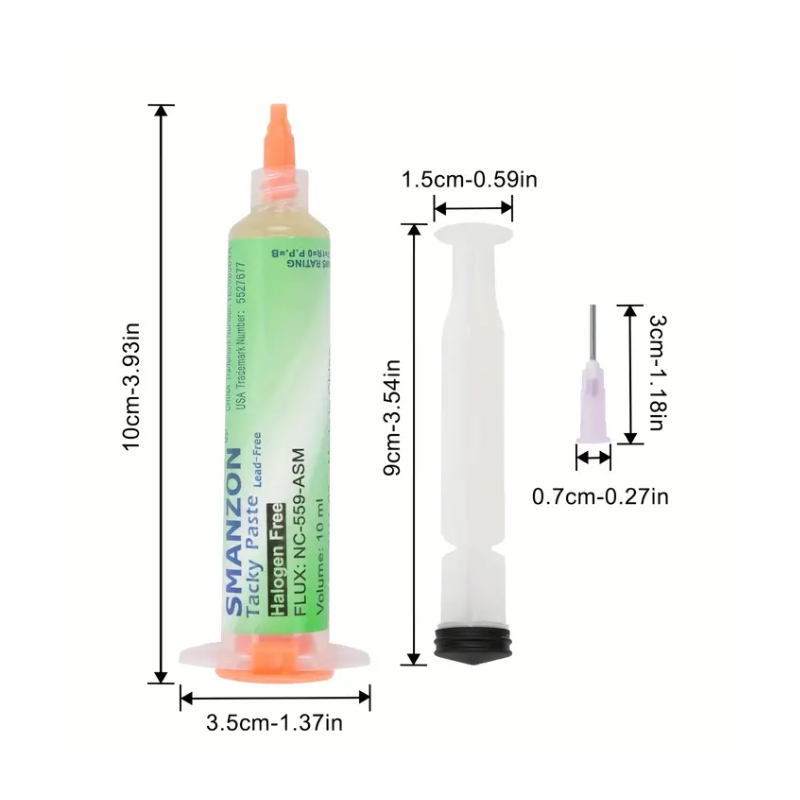

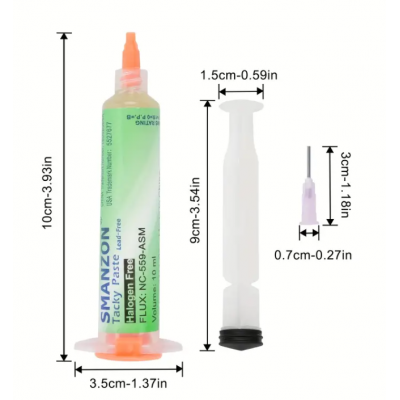

SMANZON NC-559 Soldering Flux, No-Clean Flux Paste Syringe (10g/PCS)

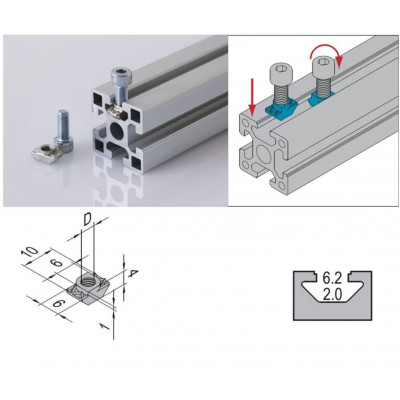

NOTE: Optional - Dispencing handle (SKU 3421)

NC-559-ASM is a high-activity, no‑clean soldering flux paste formulated to promote fast wetting, excellent solderability and strong solder joints for both production and repair work. Designed for hand soldering, rework and touch-up applications, this flux delivers consistent performance on common PCB finishes (HASL, ENIG, OSP) and components. Its no‑clean formulation leaves minimal non‑conductive residues, reducing the need for post‑solder cleaning in many applications — though cleaning is recommended for sensitive electronics and high-reliability assemblies.

Key features

- High-activity flux chemistry for rapid wetting and improved solder flow

- No‑clean formulation: low, non‑conductive residues under normal conditions

- Ideal for hand soldering, SMD rework, BGA/IC reflow touch‑ups and through‑hole repair

- Compatible with common solder alloys (Sn-Pb, SAC305, SACX)

- Smooth, paste-like consistency — easy to apply with syringe or brush

- Enhances joint reliability and reduces solder bridges and cold joints

- Temperature stable for typical soldering profiles

- Available in multiple syringe sizes (e.g., 10 g, 25 g) depending on vendor

Typical specifications

- Product type: No‑clean rosin-based solder flux paste

- Activity level: High (for difficult to wet surfaces and oxidized pads)

- Appearance: Amber/yellow paste (may vary slightly by batch)

- Viscosity/consistency: Syringe-ready paste

- Compatibility: Works with Sn-Pb and lead-free alloys (e.g., SAC305)

- Shelf life: Typically 12–24 months when stored sealed at recommended conditions (check manufacturer label)

- Storage: Store in cool, dry place away from direct sunlight; avoid freezing

What’s included

- 1 × NC-559-ASM flux paste syringe (size as selected)

- 1 x dispensing tip (depending on product variant) — check product variant details

- Optional: Dispencing handle (SKU 3421)

Usage & application notes

Apply small amount to pads or component leads using the syringe tip, fine brush or applicator. Solder immediately after flux application for best results; if left exposed, active compounds may diminish. For rework, apply flux to component pads and leads, then heat with soldering iron or hot-air rework station following recommended temperature profiles. Excessive application can increase residue — use sparingly for cleaner results.

Safety & handling

- Contains active chemicals and rosin derivatives. Avoid skin and eye contact.

- Use in well‑ventilated area. Avoid inhalation of fumes during soldering — use fume extraction when possible.

- Wear protective gloves and safety glasses when handling. Wash hands after use.

- Keep out of reach of children. Not for consumer consumption.

- Refer to the product Safety Data Sheet (SDS) for full hazard, first‑aid, handling and disposal information.

Compatibility & cleaning

- Suitable for PCBs finished with HASL, ENIG, OSP and other common surface finishes.

- No‑clean residues are typically non‑conductive and acceptable for many applications; however, for high‑reliability or conformal-coated electronics, clean residues with an appropriate flux remover (IPA, specialized flux cleaner) following manufacturer recommendations.

- Confirm compatibility with sensitive components and plated finishes in critical applications.

Common use cases

- Electronics assembly bench work and production touch‑ups

- SMD rework and BGA/IC re-soldering

- Through‑hole component repair and lead forming

- Hobbyist and maker projects requiring reliable joints

No customer reviews for the moment.