TIANKONGRC TS90A 9gram 360Deg continuous rotation Micro Servo Analog

Delivery: 2-5 working days

This mini servo only weights 9 grams and gives you a 1.6kg cm torque 360 Degrees continuous rotation. Ideally suited for Arduino projects to create motion.

Description:

SG90 analog servo's is by far the most commonly used servos for DIY projects. This is due to several factors but largely due to its low cost and ease of use. These servos have 360 degrees of movement and comes with a range of control arms and mounting screws.

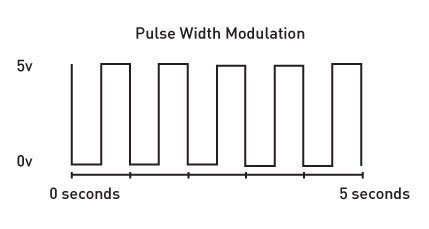

Controlling Servo Motors with PWM:

Pulse width modulation (PWM) sends an electric pulse of variable width to the motor. With PWM there is a minimum pulse, maximum pulse, and a repetition rate. The rotor will turn to the desired position based on the duration of the pulse. When servos are commanded to move, they move to the position and hold the position.

Pulse Width Modulation Graph for Servo Motors

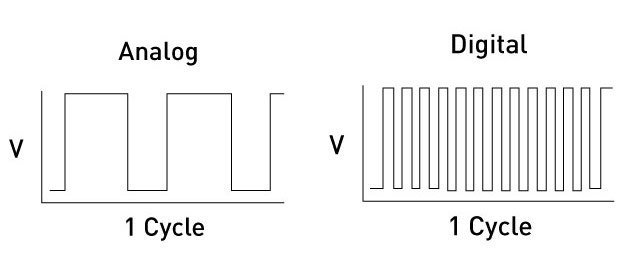

Analog and digital servo motors look exactly the same. The difference is in the way they signal and process information.

Analog Servos operate based on voltage signals that come through the pulse width modulation (PWM). When an analog servo is at rest, the PWM is essentially off unless you transmit some action. Producing torque from the resting mode makes the initial reaction time sluggish. This delay in torque isn’t ideal for advanced applications.

Digital Servos use a small microprocessor to receive and direct action at high-frequency voltage pulses. The digital servo sends nearly six times the amount of pulses an analog signal does. These faster pulses provide consistent torque for quicker and smoother response times. It’s important to note the faster pulses require more power emission from the motor.

Analog Servo Motors vs Digital Servo Motors Pulse Width Modulation

Analog Servo Motors vs Digital Servo Motors Pulse Width ModulationNo customer reviews for the moment.